Glass products encompass a wide range of items that serve various purposes in residential, commercial, and industrial areas.

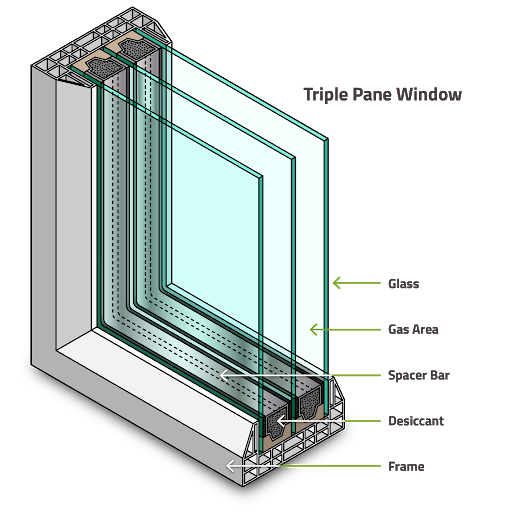

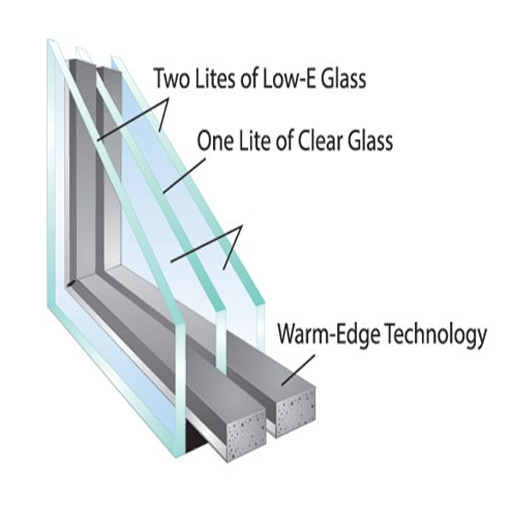

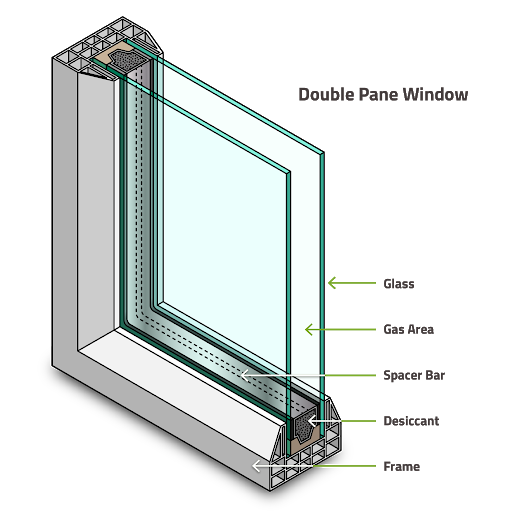

Insulated glass, also known as double glazing, is a type of glass construction consisting of two or more glass panes separated by a vacuum or gas-filled space. It enhances thermal insulation, and soundproofing, and reduces condensation.

Heat-strengthened glass is similar to tempered glass except that the cooling is done at a much slower pace. Annealed glass is heated to approximately 650-700 º C, but the cooling process is slower than that for tempered glass. Heat-strengthened glass is about twice as strong as annealed glass of the same size and thickness.

Heat-strengthened glass is semi-tempered glass that retains the normal properties of ordinary float glass. Heat Strengthened glass has been strengthened thermally by inducing a surface compression of 6000 to 9000 psi as compared to a range of 11000 to 20000 psi in the case of fully tempered glass.

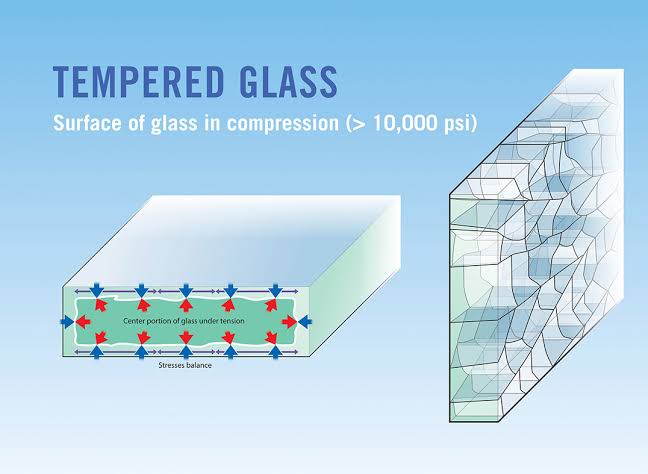

Heat strengthening adds strength to the glass while limiting the change in its breakage characteristics. The cooling process places the glass surfaces in a state of high compression and the central core in a state of compensating tension.

Tempering is a process in which pre-processed glass is uniformly heated in a Roller Hearth Oscillating Tempering Furnace. Uniform heating is obtained by conduction, convection, and radiation.

Typically, the glass is heated to about 620˚C, with a specified duration of time ( usually at about 40 secs/mm thick of the glass), then rapidly cooled or quenched by simultaneously blowing an evenly distributed cool air using high-pressure air nozzles on both surfaces.

When the hot glass is cooled rapidly, the surface of the glass cools faster and hence builds compressive stresses while the center of the glass is still under expansion and hence builds tensile stress.